Crazy bearings: How does a small steel ball shake up the entire industrial world?

Crazy bearings: How does a small steel ball shake up the entire industrial world?

You may pass by it every day without noticing its existence. It is hidden in your electric car wheel, hair dryer, watch, and even in the grinder you use to make coffee in the morning. It is not a chip or a motor, but it silently undertakes one of the most critical tasks in the entire mechanical world - it is the bearing.

But wait, is a small steel ball really that magical? Today we will talk about how crazy this "silent hero" is!

If modern industry is compared to a superhero team, then the bearing is the member who doesn't like to talk but is extremely powerful. Do you know how many revolutions per minute an airplane engine makes? Some can reach as high as 100,000 revolutions per minute! Without the support of bearings, such rotation would have ground the axis into iron filings long ago.

Not just airplanes - cars, trains, mobile phones, robots, wind turbines... As long as there is "rotation", there are basically bearings. The TikTok you watch uses a stable gimbal equipped with precision bearings; the electric car you order for takeout relies on wheel hub bearings to rotate smoothly; the fan radiator you use to edit videos at night also has micro bearings working silently.

The "circle of friends" of bearings is no longer a question of whether it is wide or not, but **"Without it, you can't start the game at all.

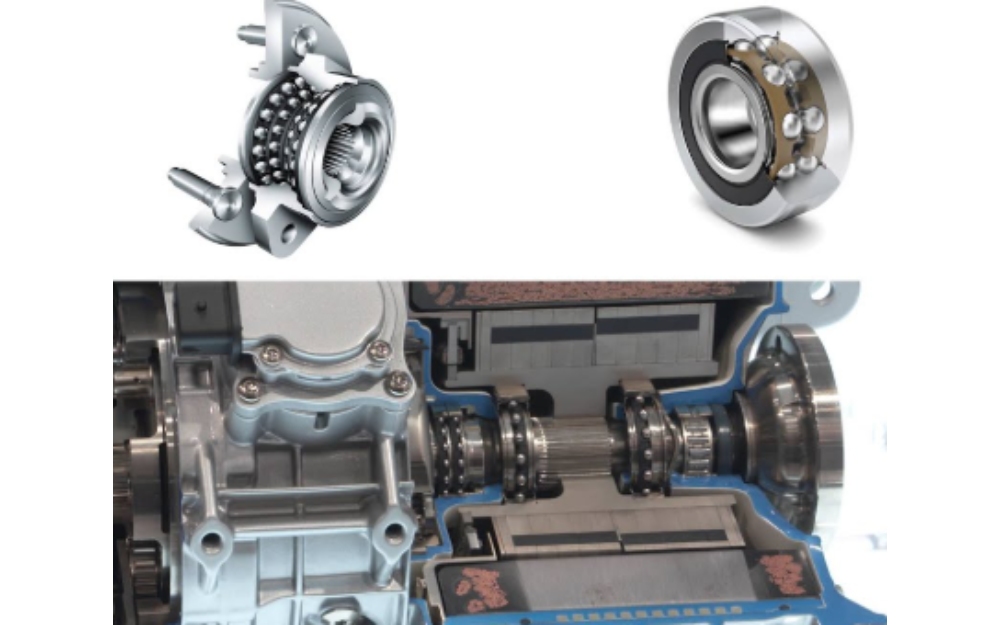

Let's "dissect" an ordinary bearing. It usually consists of the following parts:

Inner ring and outer ring: like two rings, fixed on the shaft and the housing respectively;

Rolling element: commonly small steel balls, or rollers;

Cage: prevent rolling elements from hitting each other;

Lubricant: such as grease, which makes it turn more smoothly.

These parts work together to make a high-speed rotating device stable and durable. Like a perfect ensemble, the steel ball is the protagonist, but every part is indispensable.

In high-end applications such as miniature bearings, high-temperature bearings, and vacuum bearings, the material selection even includes ceramics, titanium alloys, and composite resins, which directly maximizes the sense of technology.

Crazy bearings: How does a small steel ball shake up the entire industrial world?

Crazy bearings: How does a small steel ball shake up the entire industrial world?

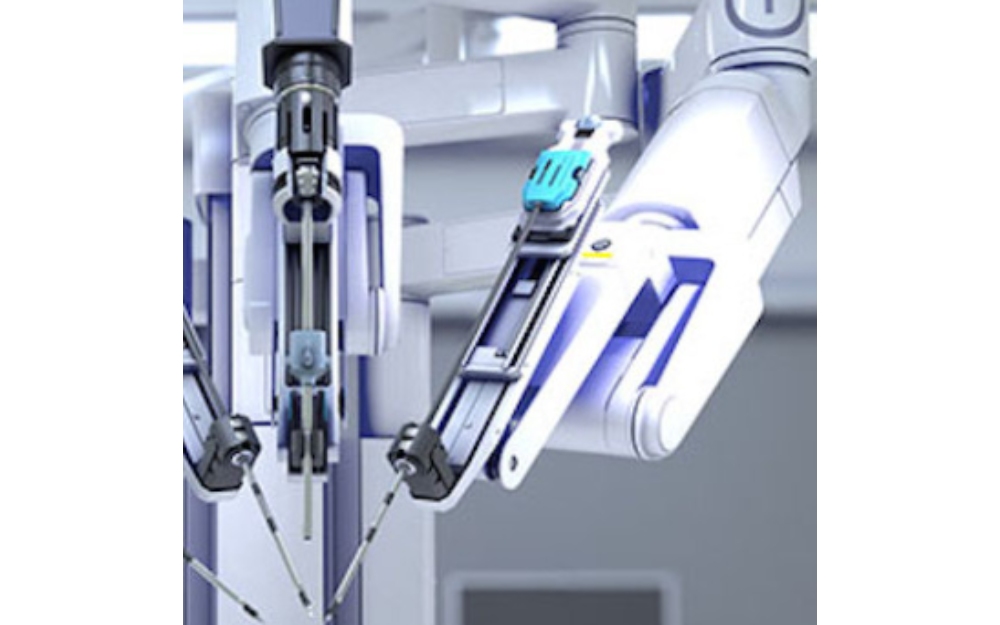

High-end products such as robot bearings have successfully entered the Japanese market!

High-end products such as robot bearings have successfully entered the Japanese market!

Micro but Mighty: The Rise of Miniature Bearings in Wearables and Medical Devices

Micro but Mighty: The Rise of Miniature Bearings in Wearables and Medical Devices

Why Your Robot’s Having a Midlife Crisis (Hint: It’s the Bearings)

Why Your Robot’s Having a Midlife Crisis (Hint: It’s the Bearings)